- User Manual For A Sharp Cd-c406 Youtube

- User Manual For A Sharp Cd-c406 Guitar

- User Manual For A Sharp Cd-c406 Home

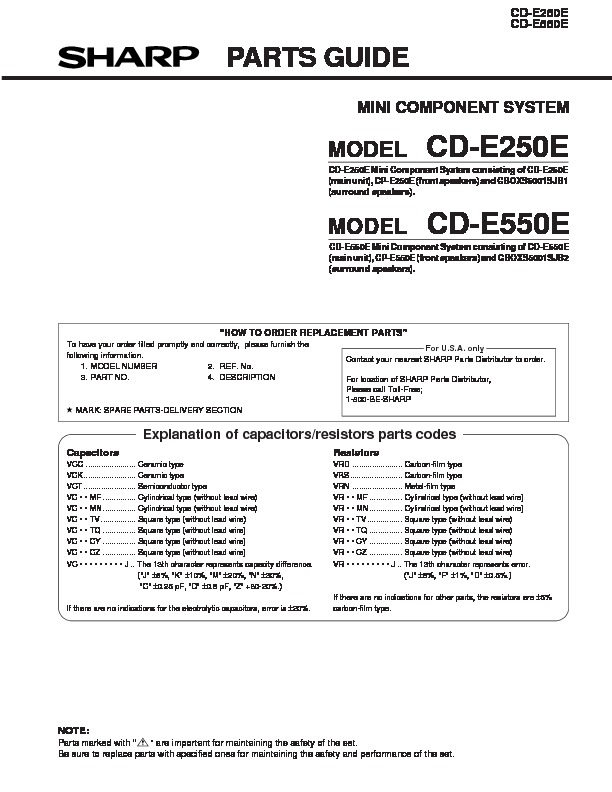

Service (repair) manual for Sharp CD-C406 (original from manufacturer) Definition Depending on the type of product, a service manual includes schematic and block diagrams, printed wiring boards, waveforms, parameters and IC pin descriptions, parts list, drawings and schematics of mechanisms.

A hard disk drive failure occurs when a hard disk drive malfunctions and the stored information cannot be accessed with a properly configured computer.

A hard disk failure may occur in the course of normal operation, or due to an external factor such as exposure to fire or water or high magnetic fields, or suffering a sharp impact or environmental contamination, which can lead to a head crash.

Hard drives may also be rendered inoperable through data corruption, disruption or destruction of the hard drive's master boot record, or through malware deliberately destroying the disk's contents.

- 2Signs of drive failure

- 2.1Landing zones and load/unload technology

Causes[edit]

Some hard disk drives simply fail because of worn out parts,[1][clarification needed] others fail prematurely. Drive manufacturers typically specify a mean time between failures (MTBF) or an annualized failure rate (AFR) which are population statistics that can't predict the behavior of an individual unit.[2] These are calculated by constantly running samples of the drive for a short period of time, analyzing the resultant wear and tear upon the physical components of the drive, and extrapolating to provide a reasonable estimate of its lifespan. Hard disk drive failures tend to follow the concept of the bathtub curve.[3] Drives typically fail within a short time if there is a defect present from manufacturing. If a drive proves reliable for a period of a few months after installation, the drive has a significantly greater chance of remaining reliable. Therefore, even if a drive is subjected to several years of heavy daily use, it may not show any notable signs of wear unless closely inspected. On the other hand, a drive can fail at any time in many different situations.

The most notorious cause of drive failure is a head crash, where the internal read-and-write head of the device, usually just hovering above the surface, touches a platter, or scratches the magneticbumps' in a landing zone,[7] thus vastly improving stiction and wear performance. This technology is still largely in use today, predominantly in desktop and enterprise (3.5-inch) drives. In general, CSS technology can be prone to increased stiction (the tendency for the heads to stick to the platter surface), e.g. as a consequence of increased humidity. Excessive stiction can cause physical damage to the platter and slider or spindle motor.

Unloading[edit]

Load/unload technology relies on the heads being lifted off the platters into a safe location, thus eliminating the risks of wear and stiction altogether. The first HDD RAMAC and most early disk drives used complex mechanisms to load and unload the heads. Modern HDDs use ramp loading, first introduced by Memorex in 1967,[8] to load/unload onto plastic 'ramps' near the outer disk edge.

Addressing shock robustness, IBM also created a technology for their ThinkPad line of laptop computers called the Active Protection System. When a sudden, sharp movement is detected by the built-in accelerometer in the Thinkpad, internal hard disk heads automatically unload themselves to reduce the risk of any potential data loss or scratch defects. Apple later also utilized this technology in their PowerBook, iBook, MacBook Pro, and MacBook line, known as the Sudden Motion Sensor. Sony,[9] HP with their HP 3D DriveGuard[10] and Toshiba[11] have released similar technology in their notebook computers.

Modes of failure[edit]

Hard drives may fail in a number of ways. Failure may be immediate and total, progressive, or limited. Data may be totally destroyed, or partially or totally recoverable.

Earlier drives had a tendency toward developing bad sectors with use and wear; these bad sectors could be 'mapped out' so they were not used and did not affect operation of a drive, and this was considered normal unless many bad sectors developed in a short period of time. Some early drives even had a table attached to a drive's case on which bad sectors were to be listed as they appeared.[12] Later drives map out bad sectors automatically, in a way invisible to the user; a drive with remapped sectors may continue to be used. Statistics and logs available through S.M.A.R.T (Self-Monitoring, Analysis, and Reporting Technology) provide information about the remapping.

Other failures, which may be either progressive or limited, are usually considered to be a reason to replace a drive; the value of data potentially at risk usually far outweighs the cost saved by continuing to use a drive which may be failing. Repeated but recoverable read or write errors, unusual noises, excessive and unusual heating, and other abnormalities, are warning signs.

- Head crash: a head may contact the rotating platter due to mechanical shock or other reason. At best this will cause irreversible damage and data loss where contact was made. In the worst case the debris scraped off the damaged area may contaminate all heads and platters, and destroy all data on all platters. If damage is initially only partial, continued rotation of the drive may extend the damage until it is total.[13]

- Bad sectors: some magnetic sectors may become faulty without rendering the whole drive unusable. This may be a limited occurrence or a sign of imminent failure.

- Stiction: after a time the head may not 'take off' when started up as it tends to stick to the platter, a phenomenon known as stiction. This is usually due to unsuitable lubrication properties of the platter surface, a design or manufacturing defect rather than wear. This occasionally happened with some designs until the early 1990s.

- Circuit failure: components of the electronic circuitry may fail making the drive inoperable.

- Bearing and motor failure: electric motors may fail or burn out, and bearings may wear enough to prevent proper operation.

- Miscellaneous mechanical failures: parts, particularly moving parts, of any mechanism can break or fail, preventing normal operation, with possible further damage caused by fragments.

Metrics of failures[edit]

Most major hard disk and motherboard vendors support S.M.A.R.T, which measures drive characteristics such as operating temperature, spin-up time, data error rates, etc. Certain trends and sudden changes in these parameters are thought to be associated with increased likelihood of drive failure and data loss. However, S.M.A.R.T. parameters alone may not be useful for predicting individual drive failures.[14] While several S.M.A.R.T. parameters affect failure probability, a large fraction of failed drives do not produce predictive S.M.A.R.T. parameters.[14] Unpredictable breakdown may occur at any time in normal use, with potential loss of all data. Recovery of some or even all data from a damaged drive is sometimes, but not always possible, and is normally costly.

A 2007 study published by Google suggested very little correlation between failure rates and either high temperature or activity level. Indeed, the Google study indicated that 'one of our key findings has been the lack of a consistent pattern of higher failure rates for higher temperature drives or for those drives at higher utilization levels.'.[15] Hard drives with S.M.A.R.T.-reported average temperatures below 27 °C (81 °F) had higher failure rates than hard drives with the highest reported average temperature of 50 °C (122 °F), failure rates at least twice as high as the optimum S.M.A.R.T.-reported temperature range of 36 °C (97 °F) to 47 °C (117 °F).[14] The correlation between manufacturers, models and the failure rate was relatively strong. Statistics in this matter are kept highly secret by most entities; Google did not relate manufacturers' names with failure rates,[14] though it has been revealed that Google uses Hitachi Deskstar drives in some of its servers.[16]

Google's 2007 study found, based on a large field sample of drives, that actual annualized failure rates (AFRs) for individual drives ranged from 1.7% for first year drives to over 8.6% for three-year-old drives.[17] A similar 2007 study at CMU on enterprise drives showed that measured MTBF was 3–4 times lower than the manufacturer's specification, with an estimated 3% mean AFR over 1–5 years based on replacement logs for a large sample of drives, and that hard drive failures were highly correlated in time.[18]

A 2007 study of latent sector errors (as opposed to the above studies of complete disk failures) showed that 3.45% of 1.5 million disks developed latent sector errors over 32 months (3.15% of nearline disks and 1.46% of enterprise class disks developed at least one latent sector error within twelve months of their ship date), with the annual sector error rate increasing between the first and second years. Enterprise drives showed less sector errors than consumer drives. Background scrubbing was found to be effective in correcting these errors.[19]

SCSI, SAS, and FC drives are more expensive than consumer-grade SATA drives, and usually used in servers and disk arrays, where SATA drives were sold to the home computer and desktop and near-line storage market and were perceived to be less reliable. This distinction is now becoming blurred.

The mean time between failures (MTBF) of SATA drives is usually specified to be about 1.2 million hours (some drives such as Western Digital Raptor have rated 1.4 million hours MTBF),[20] while SAS/FC drives are rated for upwards of 1.6 million hours.[21] However, independent research indicates that MTBF is not a reliable estimate of a drive's longevity (service life).[22] MTBF is conducted in laboratory environments in test chambers and is an important metric to determine the quality of a disk drive, but is designed to only measure the relatively constant failure rate over the service life of the drive (the middle of the 'bathtub curve') before final wear-out phase.[18][23][24] A more interpretable, but equivalent, metric to MTBF is annualized failure rate (AFR). AFR is the percentage of drive failures expected per year. Both AFR and MTBF tend to measure reliability only in the initial part of the life of a hard disk drive thereby understating the real probability of failure of a used drive.[25]

The cloud storage company Backblaze produces an annual report into hard drive reliability. However the company states that it mainly uses commodity consumer drives, which are deployed in enterprise conditions, rather than in their representative conditions and for their intended use. Consumer drives are also not tested to work with enterprise RAID cards of the kind used in a datacenter, and may not respond in the time a RAID controller expects; such cards will be identified as having failed when they have not.[citation needed] The result of tests of this kind may be relevant or irrelevant to different users, since they accurately represent the performance of consumer drives in the enterprise or under extreme stress, but may not accurately represent their performance in normal or intended use.[citation needed]

Example drive families with high failure rates[edit]

- IBM 3380 DASD, 1984 ca.[26]

- Computer Memories Inc. 20MB HDD for PC/AT, 1985 ca.[27]

- Fujitsu MPG3 and MPF3 series, 2002 ca.[28]

- IBM Deskstar 75GXP, 2001 ca.[29]

- Seagate ST3000DM001, 2012 ca.[30]

Mitigation[edit]

User Manual For A Sharp Cd-c406 Youtube

In order to avoid the loss of data due to disk failure, common solutions include:

- Data backup, to allow restoration of data after a failure

- Data scrubbing, to detect and repair latent corruption

- Data redundancy, to allow systems to tolerate failures of individual drives

- Active hard-drive protection, to protect laptop drives from external mechanical forces

- S.M.A.R.T. (Self-Monitoring, Analysis, and Reporting Technology) included in hard-drives, to provide early warning of predictable failure modes

- Base isolation used under server racks in data centers

Data recovery[edit]

Data from a failed drive can sometimes be partially or totally recovered if the platters' magnetic coating is not totally destroyed. Specialised companies carry out data recovery, at significant cost, by opening the drives in a clean room and using appropriate equipment to read data from the platters directly. If the electronics have failed, it is sometimes possible to replace the electronics board, though often drives of nominally exactly the same model manufactured at different times have different circuit boards that are incompatible. Moreover, electronics boards of modern drives usually contain drive-specific adaptation data required for accessing their system areas, so the related componentry needs to be either reprogrammed (if possible) or unsoldered and transferred between two electronics boards.[31][32]

Sometimes operation can be restored for long enough to recover data, perhaps requiring reconstruction techniques such as file carving. Risky techniques are justifiable if the drive is otherwise dead. If a drive is started up once it may continue to run for a shorter or longer time but never start again, so as much data as possible is recovered as soon as the drive starts. A 1990s drive that does not start due to stiction can sometimes be started by tapping it or rotating the body of the drive rapidly by hand.

References[edit]

- ^Lee, Joel. 'How To Care For Your Hard Drives And Make Them Last Longer'. Make Use Of. Retrieved 9 February 2016.

- ^Scheier, Robert. 'Study: Hard Drive Failure Rates Much Higher Than Makers Estimate'. PC World. Retrieved 9 February 2016.

- ^'How long do hard drives actually live for?'. ExtremeTech. Retrieved August 3, 2015.

- ^'Definition of:hard disk defect management'. PC Mag.

- ^Quirke, Chris. 'Hard Drive Data Corruption'. Archived from the original on 26 December 2014.

- ^'Barracuda 7200.10 Serial ATA Product Manual'(PDF). Retrieved 26 April 2012.

- ^IEEE.org, Baumgart, P.; Krajnovich, D.J.; Nguyen, T.A.; Tam, A.G.; IEEE Trans. Magn.

- ^Pugh et al.; 'IBM's 360 and Early 370 Systems'; MIT Press, 1991, pp.270

- ^'Sony | For Business | VAIO SMB'. B2b.sony.com. Retrieved 13 March 2009.

- ^'HP.com'(PDF). Retrieved 26 April 2012.

- ^'Toshiba HDD Protection measures'(PDF). Retrieved 26 April 2012.

- ^Adaptec ACB-2072 XT to RLL Installation Guide A defect list 'may be put in from a file or entered from a keyboard.'

- ^'Hard Drives'. escotal.com. Retrieved 16 July 2011.

- ^ abcdEduardo Pinheiro, Wolf-Dietrich Weber and Luiz André Barroso (February 2007). Failure Trends in a Large Disk Drive Population(PDF). 5th USENIX Conference on File and Storage Technologies (FAST 2007). Retrieved 15 September 2008.

- ^Conclusions: Failure Trends in Large Disk Drive Population, p. 12

- ^Shankland, Stephen (1 April 2009). 'CNet.com'. News.cnet.com. Retrieved 26 April 2012.

- ^AFR broken down by age groups: Failure Trends in Large Disk Drive Population, p. 4, figure 2 and subsequent figures.

- ^ abBianca Schroeder and Garth A. Gibson. ''Disk Failures in the Real World: What Does an MTTF of 1,000,000 Hours Mean to You?'. Proceedings 5th USENIX Conference on File and Storage Technologies. 2007'.

- ^'L.N. Bairavasundaram, GR Goodson, S. Pasupathy, J.Schindler. 'An analysis of latent sector errors in disk drives'. Proceedings of SIGMETRICS'07, June 12-16,2007'(PDF).

- ^'WD VelociRaptor Drive Specification Sheet (PDF)'(PDF). Retrieved 26 April 2012.

- ^Jay White (May 2013). 'Technical Report: Storage Subsystem Resiliency Guide (TR-3437)'(PDF). NetApp. p. 5. Retrieved 6 January 2016.

- ^'Everything You Know About Disks Is Wrong'. StorageMojo. 20 February 2007. Retrieved 29 August 2007.

- ^'One aspect of disk failures that single-value metrics such as MTTF and AFR cannot capture is that in real life failure rates are not constant. Failure rates of hardware products typically follow a 'bathtub curve' with high failure rates at the beginning (infant mortality) and the end (wear-out) of the lifecycle.'(Schroeder et al. 2007)

- ^David A. Patterson; John L. Hennessy (13 October 2011). Computer Organization and Design, Revised Fourth Edition: The Hardware/Software Interface. Section 6.12. Elsevier. pp. 613–. ISBN978-0-08-088613-8. – '...disk manufacturers argue that the calculation [of MTBF] corresponds to a user who buys a disk and keeps replacing the disk every five years- the planned lifetime of the disk.'

- ^'Decrypting hard-drive failures – MTBF and AFR'. snowark.com.

- ^Henkel, Tom (December 24, 1984). 'IBM 3380 damage: Tip of a larger problem?'. ComputerWorld. p. 41.

- ^Burke, Steven (18 November 1985). 'Drive Problems Continue in PC AT'. InfoWorld.

- ^Krazit, Tom (22 October 2003). 'Settlement Proposed in Fujitsu Hard Disk Suit'. PCWorld.

- ^'IBM 75GXP: The infamous Deathstar'(PDF). Computer History Museum. 2000.

- ^Hruska, Joel (2 February 2016). 'Seagate faces class-action lawsuit over 3TB hard drive failure rates'. ExtremeTech.

- ^'Hard Drive Circuit Board Replacement Guide or How To Swap HDD PCB'. donordrives.com. Archived from the original on May 27, 2015. Retrieved May 27, 2015.

- ^'Firmware Adaptation Service – ROM Swap'. pcb4you.com. Archived from the original on April 18, 2015. Retrieved May 27, 2015.

See also[edit]

- Cascading failure

External links[edit]

User Manual For A Sharp Cd-c406 Guitar

| Wikibooks has a book on the topic of: Minimizing Hard Disk Drive Failure and Data Loss |

- Backblaze: Hard Drive Annual Failure Rates, 2014, 2016

- Failure Trends in a Large Disk Drive Population – Google, Inc. February 2007

You have lost your Sharp user manual?

The Japanese company Sharp was founded by Tokuji Hayakawa in 1912. Hayakawa invented the mechanical pencil that doesn't have to be sharpened, hence the company name. Today Sharp produces a wide variety of consumer products: audio-visual (TVs, Blu-ray players...), home office (calculators, telephones...), mobile phones, and home appliances (refrigerators, washing machines, air purifiers...).

If you own a Sharp product and need an instruction manual for it, all you have to do is to click on the link below and you will be forwarded to Sharp's support website. Then just choose the category of your product or the product code and the correct operating guide will show up. The company provides you also with useful information to software, drivers and installation guides.

Ideas + Know How:

User Manual For A Sharp Cd-c406 Home

Problem: My tv set Sharp 37EM33S is locked. How can i unlock the child protection code?

Solution: Power on. Press the volume down button on the front panel together with the key button on the remote control. Press the menu button on the remote control. Then press channel up to select the key sign. Press menu button again. Choose pin and enter the new code number. Press exit and then the menu button to conclude the setting.

Do you know any trick for your Sharp product that saved you a lot of time? Just let us know about it and share your knowledge with other users.